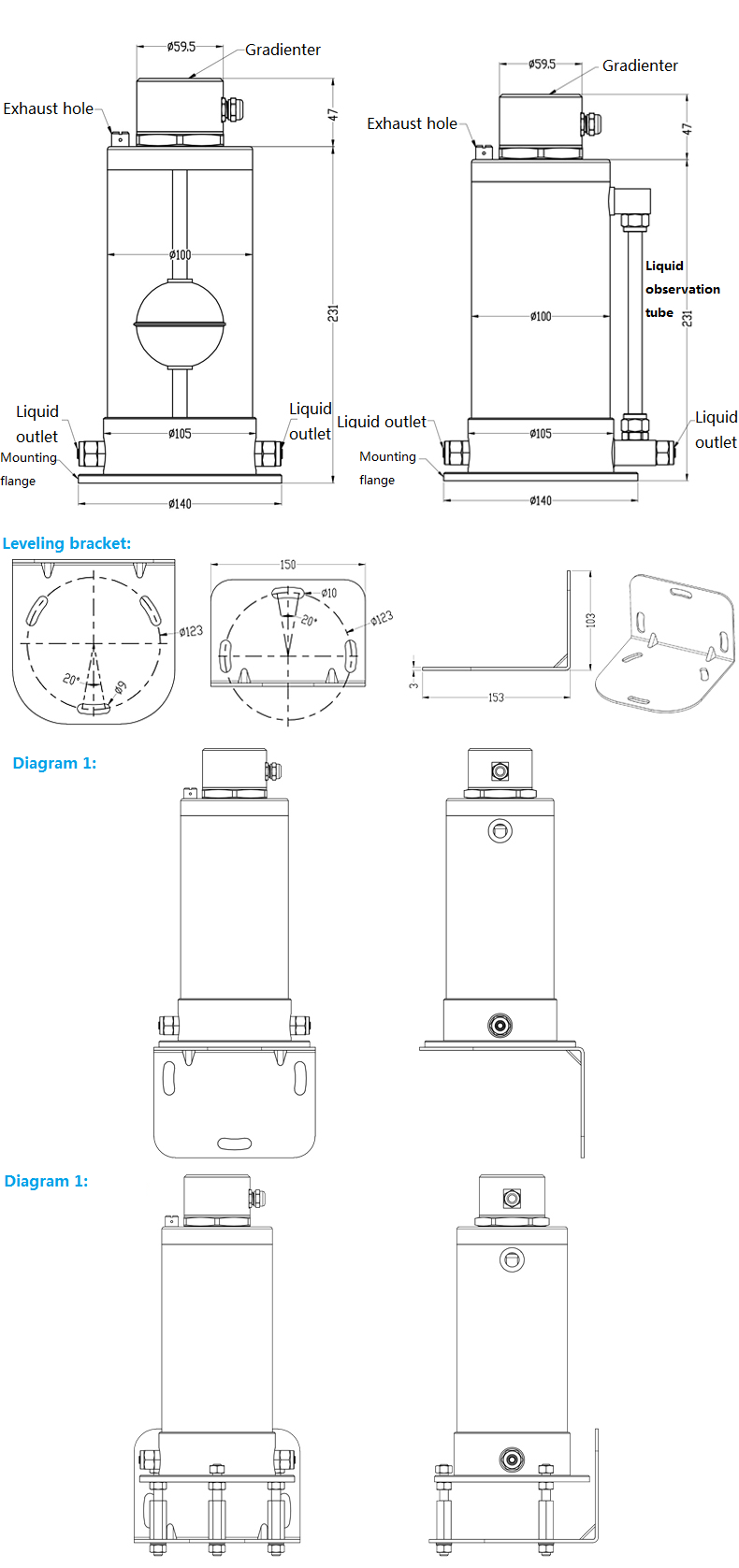

Magnetostrictive static level is a kind of high precision liquid level measuring instrument, composed of a high precision magnetostrictive liquid level gauge plus liquid storage tank, liquid level float, exhaust valve, leveling bracket, water pipe and other components. In use, a number of containers of static level are connected with a liquid pipe, the liquid level of each container is measured by the relevant sensor, and then the variation of the liquid level of each measuring point can be measured.

Magnetostrictive static level is a precision instrument used to measure the relative settlement of each measuring point of foundation and building. It is widely used in automatic monitoring of uneven settlement of structures such as DAMS, high-rise buildings, nuclear power plants, water conservancy projects, rock masses, pipelines, roadbed, cutting, Bridges, tunnels, subways and large storage tanks.

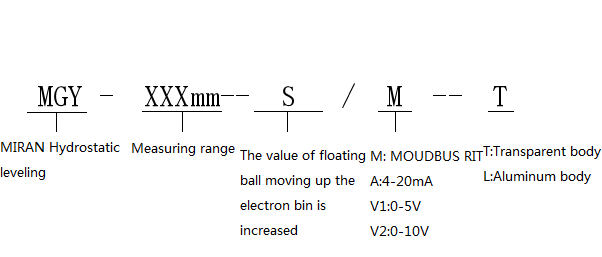

Technical Parameter

Measuring range | 80~300mm(other need customized) |

Resolution | 0.01mm |

Accuracy | ±0.1mm |

Non-linear error | ≤±0.05%FS |

Repeatability error | ≤±0.02%FS |

Working voltage | +12VDC~+24VDC |

Update frequency | General 10Hz, can be customized |

Working current | <50MA(Varies with the range) |

Output signal | RS485(MODBUS RTU) |

Temperature stability | ≤0.002%/℃ |

Environment temperature | -40°C~+85°C |

Protection class | IP67 |

Liquid storage pot | Plexiglass/aluminum alloy |

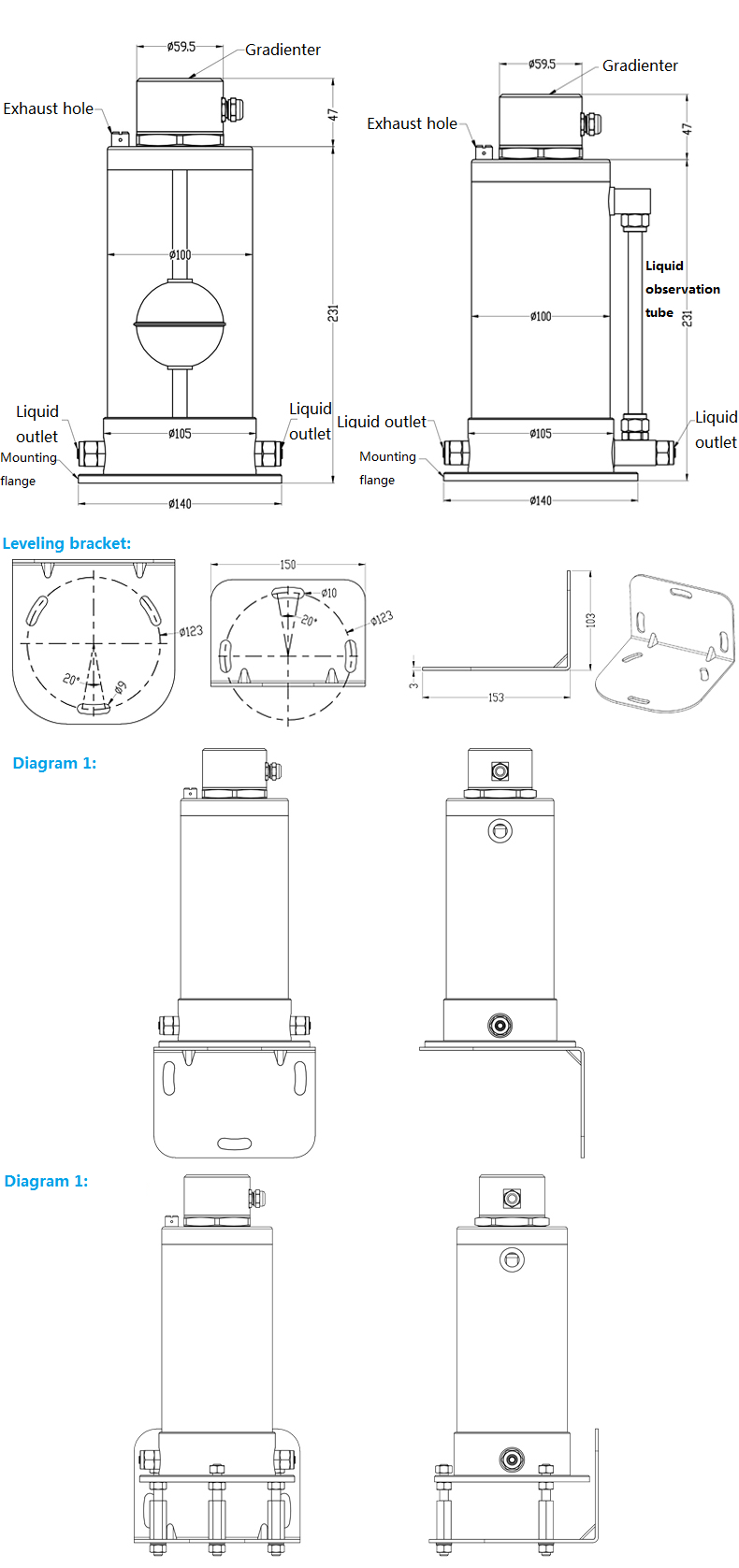

Installation Dimension

Wiring definition

Digital output:

Power supply positive (brown), power supply negative (black), RS485A(blue), RS485B (white), shell floor (shielded wire)

Analog output:

Positive power supply (brown), negative power supply (black), positive signal output (blue), negative signal output (white), shell ground (shielded wire)

The characteristics

1. The Plexiglass tube or aluminum alloy material is used as the liquid storage container, good transparency, high strength, can intuitively react the height of the liquid level in the container for visual inspection.

2. The upper cover is equipped with a level to facilitate the installation and leveling of the instrument.

3. The upper and lower end covers are made of aluminum alloy material, surface oxidation treatment, and light and rust proof.

4. The sensor is made of stainless steel and will never rust. The external structure is completely enclosed, and the waterproof performance is good.

5. The sensor installation is fixed by thread connection, without other accessories, and is simple and reliable.

6. The mounting frame is equipped with three sets of adjusting bolts to form three points of support for the instrument bottom plate, facilitating the installation and leveling of the instrument

7. The mounting frame is suitable for pier and wall installation, without adding accessories, simple and convenient fixation.